![]()

We conduct the integrated development from design to assessment of vibration absorbing rubber, ball joints, hydraulic device components, etc. Based on our accumulated store of know-how and state-of-the-art CAE analysis, we promptly offer highly reliable products.

■Nishiumi Engineering Laboratory>>

Anti-vibration rubber

Vibration and shocks transmitted from the road surface are absorbed by rubber components, reducing the effects on the chassis, and ensuring optimum link movement. Spring characteristics and durability of the rubber components are designed for vehicle conditions.

■Matching Product Torque rod>>

Linear Analysis

We design optimum shapes upon conducting linear analysis of iron and steel parts such as housing and pipes, etc.

Non-Linear Analysis

We use non-linear analysis to reproduce rubber parts that cannot be reproduced with linear analysis, and we design vibration absorbing rubber that satisfies requirements.

![]()

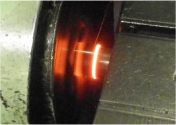

Friction Welding

A technology for welding employing the heat of friction generated when materials are brought into contact with each other in relative motion. Friction welding does not require high levels of skill, quality is considerably more stable than with arc welding, and weight is reduced. Allows welding of a wide range of pipe diameters.

■Matching Product Torque rod>>

Drag link>>

NC Bending

The use of an NC bender allows precision pipe bending over a wide range of pipe diameters and bend radii.

■Matching Product Drag link>>

Tie rod>>

Shot Peening

Shot peening of bent components changes latent tensile stress generated in the surface during bending to compressive stress, dramatically improving fatigue strength.

■Matching Product Drag link>>

Tie rod>>

Machining

Precision fabrication is required for hydraulic products, permitting fabrication to an accuracy to 1/1000mm. Introduction of a 5-axis machining center is scheduled to consolidate the production process.

■Matching Product Swivel joint>>

Clutch master Cylinder>>

Three-dimensional Measuring Instruments

This makes a major contribution not only to high-precision quality assurance but also development. By converting measured data to three-dimensional data, far more accurate design than before becomes possible and the development time can be shortened.